How is Industry 4.0 transforming manufacturing?

The essence of Industry 4.0 manufacturing lies in the combination of advanced operational technology and information technology. Data guides the physical action of manufacturing which then feeds back data on the process of creation.

Take a glimpse at how key Industry 4.0 technologies could transform your manufacturing:

THE INTERNET of THINGS (IoT)

Manufacturing systems, tools and components can be connected, monitored and accessed remotely. The data generated can improve the efficiency, productivity and speed of the entire manufacturing process.

METROLOGY

To create the increasingly sophisticated products desired by modern consumers requires intricate component parts. Using precision measurement tools, manufacturers can create complex parts accurate to less than the width of a human hair.

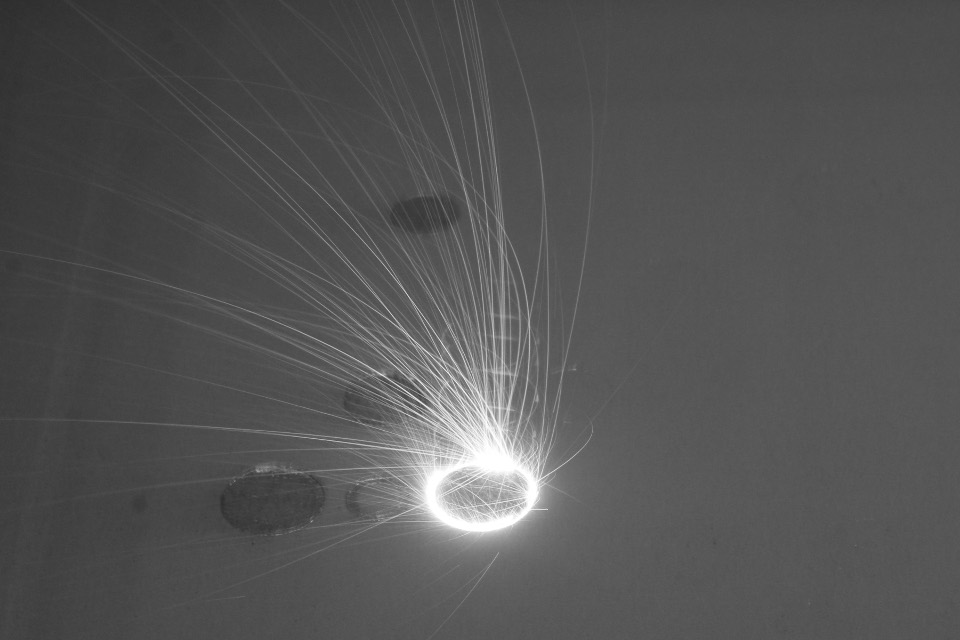

METAL 3D PRINTING

3D printing or additive manufacturing enables the production of complex shapes and quick prototyping. Industries whose products require high precision and customization currently lead in metal 3D printing adoption.

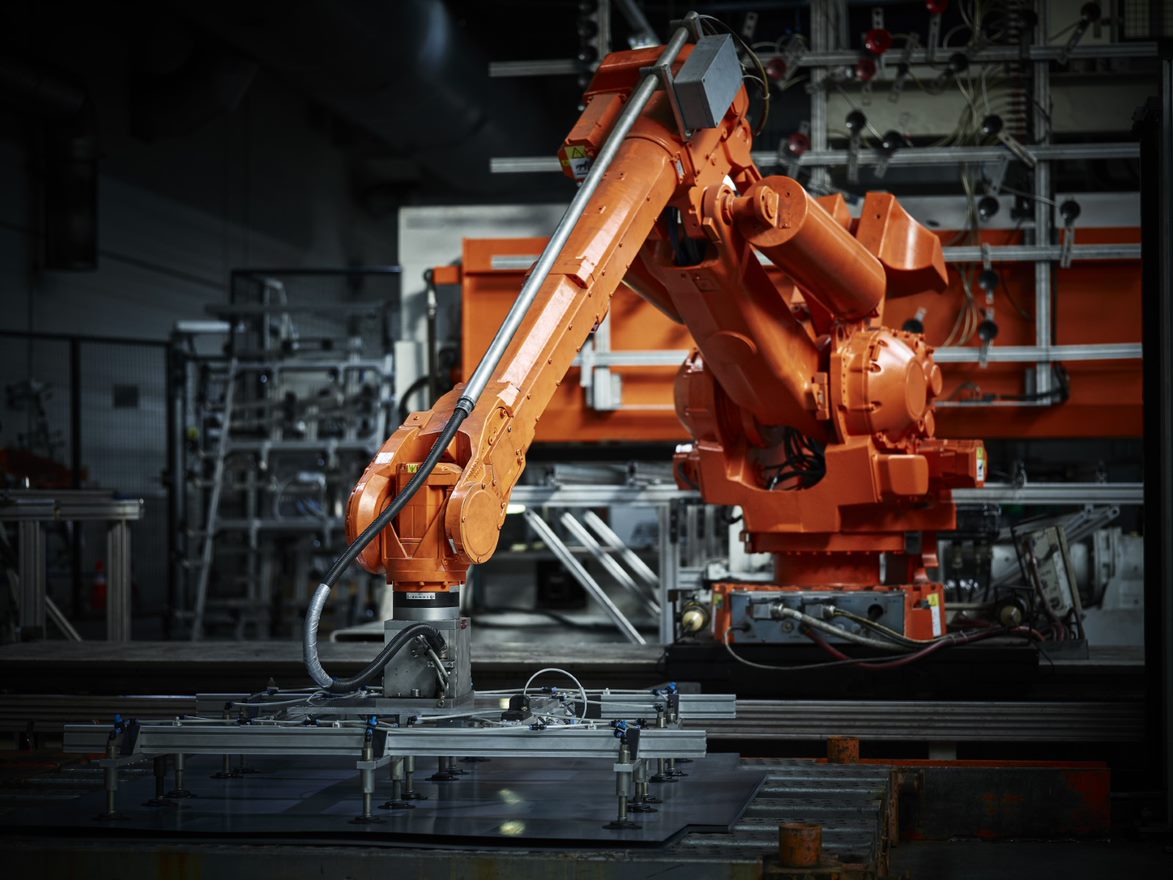

AUTONOMOUS ROBOTS

Increasingly smart robots can function with minimal human intervention to perform repetitive or delicate tasks, to reduce error and increase productivity and revenue.

ARTIFICIAL INTELLIGENCE

AI or machine learning can make sense of complex datasets and generate insights which drive machines to take quick and autonomous action, reducing inefficiencies and waste.

En

En